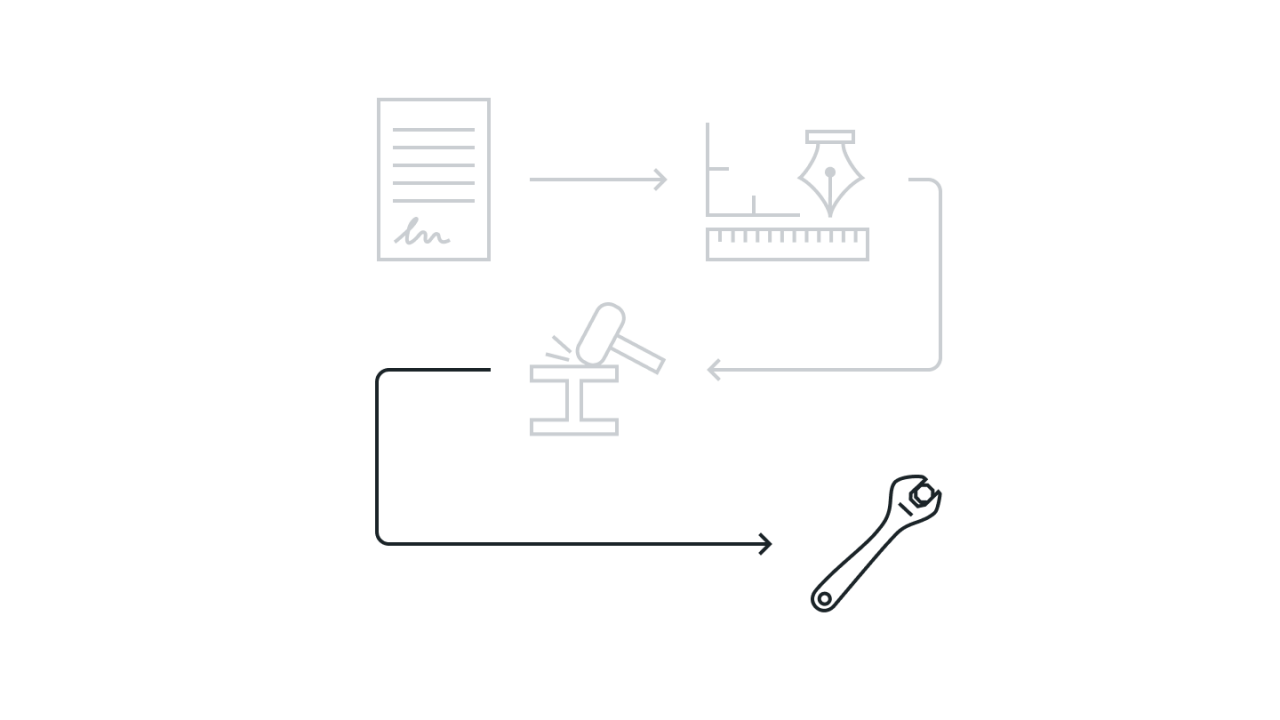

Project process

We have the entire chain. Therefore, as a client, you can feel secure knowing that everything is going to work. Below we have described the steps we normally go through in a building project where we take responsibility from concept to finished building. EAB stands for much more than just building materials.

OPTIMISED ALL THE WAY

With control from the planning and design phases to production and installation, we ensure a well-functioning building process. This allows us to optimise the use of materials, manufacturing methods and assembly time. We take responsibility for all parts of the delivery and as our client, you can spend your time doing what you do best.

ORDER > DESIGN > MANUFACTURING > INSTALLATION

ORDERS

The tender specifies all parts that are included in our scope of delivery and are the basis for an order. We begin our design process in connection with orders and we furnish preliminary designs and load distributions for basic constructions.

DESIGN

Every structure is planned in a 3D environment where it is ensured that all included components will be able to be manufactured and fitted in an effective way. You can easily see that the prefabricated components fit. Frames, walls and roof can be visualised. Necessary documents for manufacturing, assembly and documentation are drafted according to your requirements and requirements from the authorities. We are certified in accordance with SS-EN 1090 and have a Sweden Certified Steel Structural Engineer.

MANUFACTURING

We process all the steel for our finished buildings at our factory in Smålandsstenar, Sweden. We blast, cut, drill, laser cut, weld and surface treat the steel. We also manufacture our own steel fittings.

INSTALLATION

We install all components included in our scope of delivery and under our own direction if this is agreed. We have some 40 installers who are based in Smålandsstenar and we also have several of our own cranes and construction machinery.