EAB Built to last®

We’re bringing steel into the future.

The world’s first fossil-free steel makes it possible to reduce carbon dioxide emissions to nearly zero, with water as the only by-product. Together, we’re bringing steel into the future and create a more sustainable world.

Learn how to optimize and up to double your storage space

Radioshuttle® is the semi automated pallet management system and may just be EAB's most appreciated solution. Unlike other deep stacking pallet racking systems where you need to drive into the racking system with the forklift, our shuttle will retrieve or leave the desired pallet. The system allows you to fully use your warehouse volume, in all temperature zones from -30°C to +40°C. We’re now having our sixth generation of Radioshuttle® , a global success which is used in over 2000 installations worldwide.

Read about our system Radioshuttle®About EAB

EAB is a global industry leader in providing warehouse storage solutions, doors and steel buildings. Although we have a global presence, we remain a down-to-earth family company with our headquarters, production facility and product development department located in Smålandsstenar, Sweden.

Read more about us

Book a consultation

with one of our experts

Book a consultation Work at EAB

– Become one of us

EAB continues its growth, both within Sweden and internationally. That is why we always need to have more employees in our three product areas. Welcome with your application, to any of our offices in the world.

Contact one of our offices BUILT

TO LAST®

Built to last® summarises the way we think and work here at EAB, it is our promise to our customers, employees, suppliers and collaborative partners.

Built to lastlatest news

Rosti Group builds for the future

Building for the future Along national road 27 in Gislaved, just two kilometres from its current production facility, Rosti is now constructing a new 14,000-square-metre plant comprising production, warehouse, and office space. There is also potential to expand the facility to a total of 19,000 square metres. Nivika Fastigheter AB is responsible for the development…

Read more newsEnergy-efficient doors for demanding cold storage facilities at KWH Freeze

With more than 80,000 square metres of advanced, temperature-controlled warehouse space in Vantaa and 60 years of experience, KWH Freeze is Finland’s leading provider of frozen food storage. The business demands exceptional reliability and energy efficiency, which is reflected in the technical solutions chosen for its facilities. Most of the doors are installed in loading…

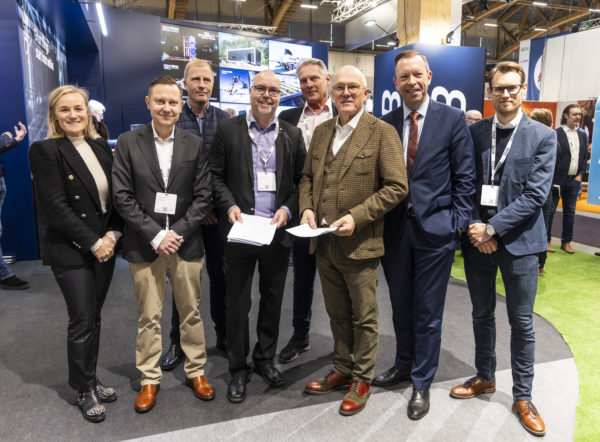

Read more newsEAB and SSAB form partnership on fossil-free steel

“Our partnership with SSAB on fossil-free grades is an important milestone in our sustainability work, and a signed agreement carries strong symbolic value. It demonstrates our commitment to driving progress – a shared promise to take steel into the future. This is not a journey you make alone. We do it together. And that feels…

Read more news